RESEARCH & DEVELOPMENT

Does your project require something beyond your capabilities? Or do you have an idea that you aren't quite sure how to achieve? Let us help by providing our R&D expertise. RAW is at the forefront of developing and utilising new technology. We have a combined 20 years of knowledge and experience custom designing, prototyping, building and implementing new, high tech camera systems with the goal to make your project or product a reality. With experience in 3D design, rapid prototyping, CNC machining and 3D printing, we can offer a one-stop solution to make your ideas a reality.

See below for some of our past projects. If you have any further questions, please get in touch.

6 AXIS STABILIZED VEHICLE MOUNT

Designed and manufactured inhouse to offer stable vibration-free footage. Multiple cameras such as RED, Black Magic, Arri, Canon, Panasonic and Sony can all be rigged and run on the system. The mount incorporates 3 axis movement dampening to help reduce large vibrations from hard cornering and fast acceleration. A high-frequency vibration dampening plate with adjustment for payloads from 4-8kg. The Crane 3S Pro gimbal offers camera control and 3 axis stabilisation at speeds over 120kph. The system was specifically designed around the Sony A7s iii offering amazingly stable results utilizing the cameras inbuilt sensor and lens stabilisation. Vibration-free footage from 24-105mm offers a huge range of possibilities when shooting. Full zoom control mixed with frame by frame perfect autofocus makes shooting with this system a breeze. Main camera control can be tricky for new operators when forced to use only a joystick based control system. The Crane 3S Pro offers a mimic/follow mode offering a far better way to follow moving subjects in a more fluid manner.

The main system can be mounted or adapted to almost any vehicle. Currently, we have options for fitment to most cars and 4x4's. Mounting utilises one hard mounting point usually a tow bar or tow strap mount along with 6 high strength suctions cups for a safe secure and quick installation.

Rigging time: Setup 10 - 15 min, Teardown 5 - 10 min

RAW MOTION CONTROL SYSTEM V2

Our new V2 motion control system will be far more advanced than our V1 system. It's reach, speed and capabilities will put it on par with many current robotic arms available today. We have finalised the initial design and have started moving onto manufacturing, with hopes to have it available for productions come late 2020.

RAW MOTION CONTROL SYSTEM V1

We have always loved the way robotics and filmmaking come together to produce stunning visual content. Systems such as the BOLT robotic arm can be prohibitively expensive for both clients and filmmakers alike. We wanted to leverage our knowledge in these fields to create a motion control system that could service a more cost-conscious customer. The design and manufacture of this MOCO rig has given us valuable insight into developing our next-generation system with greater capabilities.

AUTOMATIC OXYGEN MASK DROP SYSTEM

Aviation Australia came to us for help, further developing a way to easily and cheaply manufacture there automatic oxygen mask drop system for their Brisbane crew training facility. We decided 3D printing the main structure and pulleys for the system was the ideal path given the manufacturing run required. The system helps quickly reset the crew emergency training simulator, eliminating the need to manually repack the mask between training sessions. We took their initial prototype and revised the design in SolidWorks so it could be effectively 3D printed. After initial prototype testing and design interactions, we produced a limited manufacturing run of 30 units.

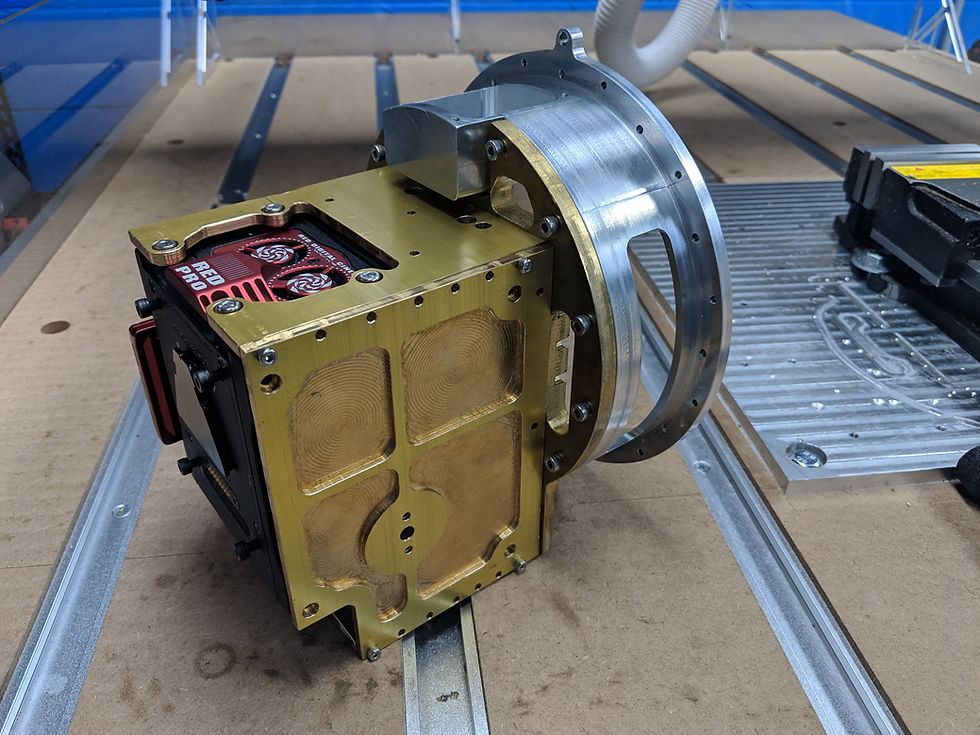

CINEFLEX ELITE RED DRAGON MOD

I was given the task to design and manufacture a new internal cage for Aerial Advantages CineFlex Elite. There is currently only one other company in the world who has completed a similar modification. The new cage gave the ability to quickly swap the original ARRI M for a RED Dragon 6k cinema camera. The initial teardown and 3D design took two weeks, once this was complete the new cage was 3D printed for test fitting. Minor adjustments to the design were made after testing and the final cage was produced from aviation grade aluminium and brass on our in-house CNC machine. The whole process from design, testing, manufacturing and final trialing was three months.

This CineFlex Elite is now currently in service and available for hire through Aerial Advantage.

CUSTOM BUILT HEAVY LIFT DRONES

Over the last 10 years, we have built and maintained many heavy lift drones for ourselves and other clients. These drones have had various uses, including, but not limited to film making, 3D mapping, thermal inspections and lidar scanning. One drone, in particular, stands out from the rest. Working closely with Industrial Pixel VFX in late 2013 we built a drone that was set up for lidar scanning, it scanned jungle terrain to make 3D models for use in the blockbuster movie, Jurassic World.

ADVANCED CAMERA STABILISATION

Back when stabilising cameras for filmmaking was difficult and not readily available we were at the forefront of designing never before seen camera stabilisation technology. The gimbal systems shown below were manufactured in-house and used on several feature films, video productions and TV shows in 2012-13.